What is a compound?

One of the most important polymer materials used in the production of plastic products is compound. When two or more raw materials are mixed together in certain proportions, a compound is obtained. In addition to the raw materials that form the main polymer bases of the compound, additives can also be added to the compound. Compound is used as a raw material in the production of plastic products and solves problems such as mixing raw materials with each other during production, wasting raw materials, and slowing down the production speed. In other words, compounds include compounds such as polymers and additives that are produced with the aim of facilitating and accelerating the process of making plastic products. Among the most famous compounds, we can mention various types of polyethylene, polypropylene, PVC, calcium carbonate, polycarbonate compounds, etc.

Why do we use compound?

Masterbatches cannot be added to the main polymer bases. In such situations, factories use Polymer compoundThey use. Using the compound prevents the products from losing quality. The compound also makes the final product hygienic and less expensive than masterbatches. Because masterbatches require cleaning and combining them with the polymer base will also be expensive.

Introduction to compound types

Polyethylene compound

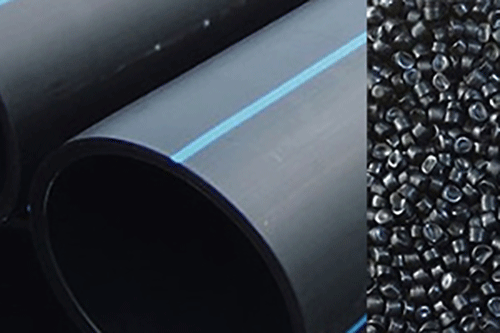

Polyethylene is produced in different grades that differ in density. To enhance some of the physical properties of polyethylene, including its strength and rigidity, some pigments are added to it during production. By combining these two materials together, which is done with a certain percentage by volume and mass, a final product is obtained, which is known as polyethylene compound.

Polyethylenes reinforced with these pigments are used in the production of blown films, pressure pipes and irrigation pipes. In order to produce water supply pipes, in addition to these pigments, some carbon black must be added to the polyethylene to ensure the best possible sealing of the pipes. The final product produced from the combination of these pigments is more stable against sunlight and is also cost-effective due to the increased lifespan of the final product.

Another positive feature that the addition of these pigments to the base polymer adds is the improvement of the plasticity of the polymer material, which allows products with more diverse shapes to be produced. The amount of compound added to the base polymer during the production process can vary according to the required application. What is currently common is to add between 40 and 100 percent of these pigments to the base polymer. These pigments help the final product to gain greater stability and stability and reduce the possibility of its deformation over time.

Types of water pipe compounding methods

Today, various pigments are used to increase the strength and durability of polymer plastic materials, which is done in this way. CompoundIt is said that the use of modern methods such as nano to add carbon black pigment to the polymer for the manufacture of water supply pipes has become very common. In general, there are two methods for compounding the components that make up water supply pipes, which we will explain below:

1- Using polyethylene grades containing prepared carbon black

In this method, polyethylene grades with a certain percentage of carbon black are manufactured by petrochemical and manufacturing companies. Companies that produce water pipes purchase these materials and use them to make polyethylene pipes.

2- Adding concentrated carbon black masterbatches to natural polyethylene

In this method, when making a pipe, a certain percentageMasterbatchThe concentration of carbon black is used to add to the material compounds. This carbon black masterbatch contains a type of carrier polyethylene and a high percentage of carbon black, which is added and mixed into the compounds when using the main polyethylene and base materials. This type of water supply pipe compounding method is considered one of the common and common methods in the pipe manufacturing industry.

Polypropylene compound

Polypropylene compound (PP compound) is widely used in industry due to its high ductility and good malleability. Polypropylene is a hard and crystalline thermoplastic that is also used in many household products, medical devices and automobiles. Other very practical characteristics of polypropylene compound include low density, high modulus of elasticity and good corrosion resistance. This material is produced using methods such as extrusion, and its aim is to increase the functionality and efficiency of this polymer material, strengthening its physical and mechanical properties by combining it with some other materials. These compounds are also produced and marketed in various colors.

What is the difference between compound and masterbatch?

Both of these materials have a polymer base. The main difference between a compound and a masterbatch is that a masterbatch cannot be added directly to the base polymer and must be used as an additive. In other words, a masterbatch is an additive that is added to the base polymer to add properties to it, but the compound is directly introduced into the machine to produce the final product; now it is possible that a masterbatch may be added to the compound used in the production process or there may be no need to add a masterbatch. We will discuss the main reasons for this below.

Improper distribution in the base polymer

One of the most fundamental issues that must be considered when adding additives to the base polymer is their proper distribution and dispersion on the surface of the base polymer. If the correct and balanced distribution of additives to the base polymer is not considered, the final product produced will not have the appropriate quality. Masterbatches cannot be added directly to the base polymer because they do not contain enough additives.

High levels of environmental pollutants

Another challenge that arises from using masterbatches directly is the creation of environmental pollutants in the workshop environment. This is because masterbatches are made up of a combination of thermoplastic materials and a type of powder. However, using the compound directly reduces the problems caused by environmental pollutants to a significant level.

Benefits of using Compound

The use of compounds has many advantages for manufacturers, which lead to the facilitation and acceleration of the production process. The most important advantages of this product include the following:

- Using uniform raw materials in manufacturing and production

- Has soot with a standard dispersion percentage

- High resistance to sunlight

- Affordable and competitive price in domestic and foreign markets

- Constant and desirable product quality

Compound production process

To produce a compound, various processes must be followed. The main process that must be considered in the production of compounds and masterbatches is the melting process. In the melting process, additives and base polymers are combined with each other in a certain ratio. The combination of these materials is done in a device called an extruder. Proper distribution of additives in the base polymer is very important in increasing the quality of the final product.

Next, the resulting mixture must be cooled so that it can be used to produce the final product. For this purpose, the desired mixture is transferred to another device, which is known as a cooler. After cooling, the desired materials take on a solid state and are then crushed into small pieces using crushing machines and marketed for use in the production of various polymer products.

What are the uses of polymer compound?

Polyethylene compound is one of the most widely used materials in the plastic industry. This material has many variations that are widely used in various polymer industries. Polyethylene compound is used by manufacturing companies in pure or mixed form, which has high quality and reasonable price.

Polyethylene compound is used in various industries, some of which include:

- Manufacturing and production of polyethylene films

- Manufacturing and production of drip irrigation pipes

- Preparation and production of pressure pipes

- Production of geomembrane sheets

- Manufacturing of plastic cartons

- Production of injection molded parts

One of the applications of polyethylene compound is the manufacture and production of pressure pipes based on PE80 containing 2 to 2.5% carbon black. These compounds are widely used in the polyethylene mastic production industry, which is most widely used in the polyethylene film production industry.

Compounds are very effective in reducing virgin polyethylene materials in industries, and many European countries use recycled compounds in the preparation and production of short-lived blown films. Also, these polyethylene compounds, if they contain a small percentage of mineral micronized powder, will significantly reduce the cost of the products.

Contact our experts to order pipe and fitting grade compound.